Looking for containment and leachate management solutions for your mine ore processing and waste disposal sites in Bonne Terre Missouri? Sovereign Hydroseal offers the best waterproofing solutions across all areas of mining leak remediation.

For further information or to explore project-specific requirements, please use our contact form, email us at info@sovereignhydroseal.com, or call us at +1 646.649.5878, and we can get started.

Heap leaching uses a solvent, such as acid or cyanide, applied to a pile or heap of crushed ore to extract metals such as gold, silver, copper, and uranium. This takes place within a heap leaching pad. That structure requires extensive containment support from liners and retaining walls.

Retaining walls used to support steep walls in leachate containment applications are mechanically stabilized earth walls made of backfill and soil reinforcement elements. These elements are then layered and fixed to the wall facing. Jet grouting is perfect for this soil improvement application. It improves soil cohesion through grouting.

Whether leachate containment is used to control water runoff from mining activities or to support the heap leaching process, waterproofing, and water sealing are essential to prevent the escape of toxic chemicals.

Jet grouting can be used to create impermeable barriers to control leachate flow and prevent any seepage. It can also build retaining walls using soil-cement columns. Jet grouting can further be used for slope stabilization to prevent erosion in or near Bonne Terre, Missouri.

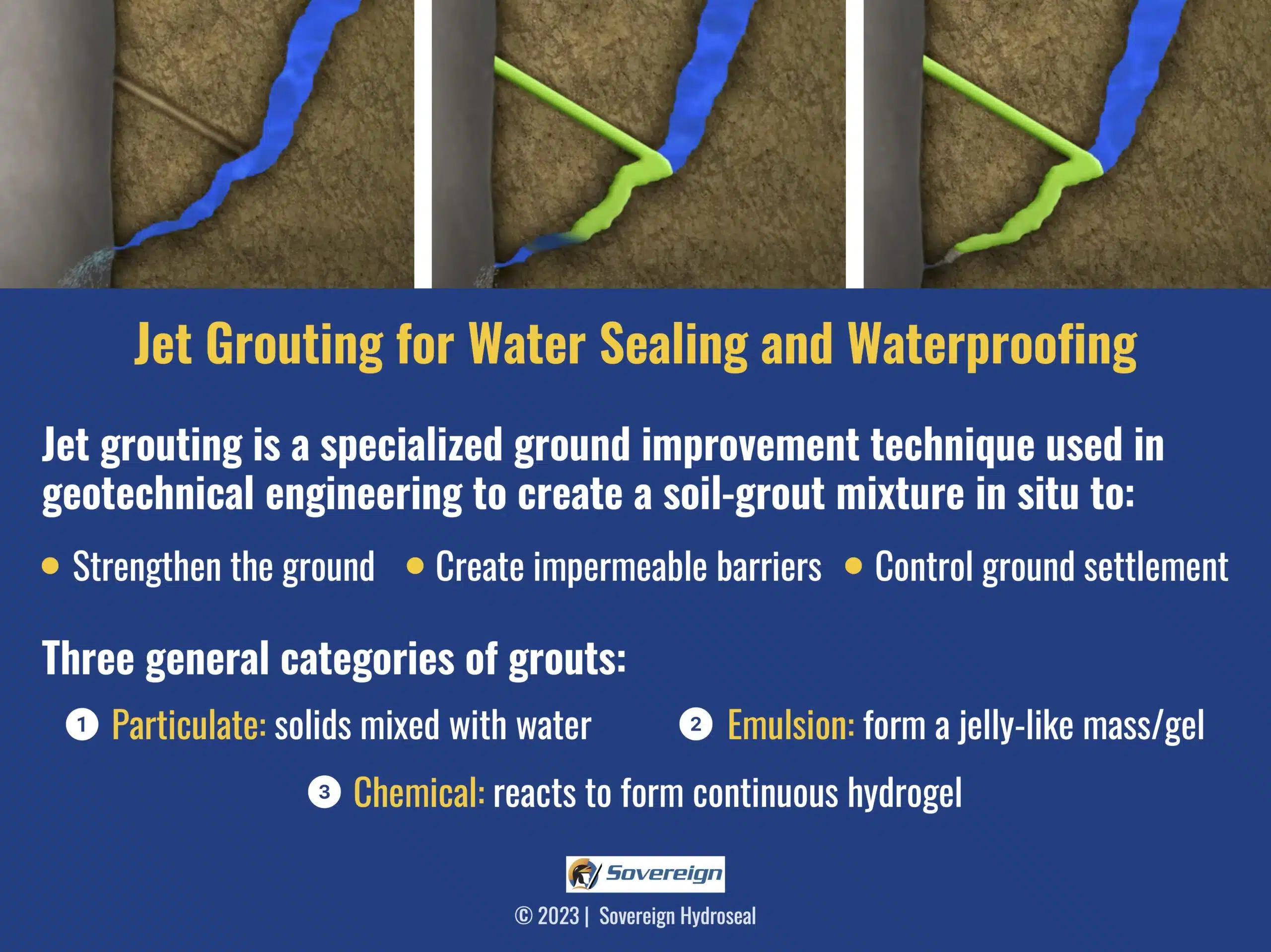

Jet grouting is a specialized ground improvement technique used in geotechnical engineering to create a soil-grout mixture in situ. It is typically employed to strengthen the ground, create impermeable barriers, and control ground settlement in or near Bonne Terre, Missouri.

Jet grouting can also be used within unconsolidated sediments above/around mines and boreholes for various containment, water sealing, and waterproofing applications. It can be further utilized in above-ground containment and leachate management applications.

There are three general categories of grouts.

Particulate. These grouts contain solids mixed with water. The water transports the solids into the concrete, rock, or soil matrix. The particles then drop out to fill the voids.

Emulsion. These grouts also use solids suspended in a water carrier. But once forced into the voids, they form a jelly-like mass or gel.

Chemical. This type of grout contains solids or liquids that dissolve in water. The solution is then injected into the voids, where it reacts to form a continuous hydrogel.

Particulate grouts contain particulate solids suspended in a fluid. These grouts include cement, cement-bentonite, and soil-water grouts. These are the primary grouts used in jet grouting to effectively create impermeable barriers to control water flow and prevent seepage. This is particularly beneficial in projects where waterproofing is crucial, including boreholes, tunnels, settling ponds, retaining or gravity walls, and diversion barriers.

Emulsion grouts contain solids or liquids dispersed in water to form minute particles. Sovereign’s polymer-based emulsion grout, NOH2O, is the only known emulsion grout known to be widely in use for curtain grouting and other injection-type applications. NOH2O is not used for jet grouting. Instead, NOH2O is a remarkable grout for sealing water-bearing cracks and fissures in mines and tunnels.

In contrast to particulate grouts, chemical grouts do not contain particles. Consequently, they are also known as solution grouts based on the combination of materials used in the grout. Chemical grouts include silicates, acrylics, and polyurethanes.

Because chemical grouts do not contain particles, they can penetrate very small fissures and pore space. Chemical grouts exhibit an initial, stable, and very low viscosity. This state is then followed by a sudden increase in viscosity immediately before gelation or curing. Gelation and set times are controlled using catalysts or inhibitors.

Sovereign Hydroseal has developed an emulsion grout that works exceptionally well in mines, tunnels, and underground infrastructure for water sealing and waterproofing. It’s a polymer-based emulsion (PBE) grout. It offers a small particle size, low viscosity in water, and can penetrate and seal water in small aperture fractures.

PBE offers three main advantages:

It can be diluted up to 15% of its original strength in water and still set effectively.

It can be used as a one-part grout, eliminating predicting set time or predetermining a mixture.

It sets when agitated, making it useful in turbulent, high-velocity water flow situations.

Chemical grouts require a chemical reaction between an agent and reagent to set. In contrast, a polymer-based emulsion grout can be set mechanically. No chemical reaction is necessary.

There are four ways to either induce or influence PBE set.

Mechanical Activation. The flow of PBE through fissures develops a high-shear action that causes the polymer colloids to flocculate. They, in turn, adhere to the side walls, forming a jelly-like mass that builds up to block the fissures.

Chemical Acceleration. A chemical activator can accelerate the PBE set if desired. It breaks the emulsion and induces the polymer colloids to coagulate in as quick as two seconds.

Chemical Retardation. If the mechanical setting happens too quickly due to high pressure, small aperture fissures, or saline water, an inhibitor chemical can be used to allow greater grout spread away from the injection point.

Atmosphere Exposure. PBE grout can also form a thin skin of very fine interlocking polymer laths when exposed to the atmosphere long enough to dehydrate.

The curing of PBE happens over two stages. It forms a jelly-like mass and then converts to a flexible rubber-like plug or membrane. It is highly adhesive and bonds to concrete or rock. At this point, it’s resistant to washout.

When fully cured, PBE is strongly bonded to the rock or concrete and is highly durable, flexible, and impermeable. Tests have shown elongation greater than 350%. It has also maintained its water-sealing properties for over four decades and counting.

From this, you can readily see that PBE grout is highly effective in controlling water intrusion and quite versatile in meeting the needs of any application.

NOH2O® is a Polymer-Based Emulsion (PBE) grout and unique water-sealing technology first developed in the 1970s. PBE is a suspension of colloidal polymer emulsoids dispersed in additives that promote flow and adhesion.

As noted above, the NOH2O® PBE is set by internal shear as the grout passes through fractures or other voids in water-bearing media. Set time may also be controlled chemically by an activator or inhibitor to regulate spread. It is differentiated from chemical/solution grouts because it is a single-part grout whose set does not require a chemical reaction.

The critical properties of NOH2O® include washout resistance in high-flow/high-pressure conditions, controlled curing rates from two seconds to several days, sets in saline and hypersaline waters, remaining flexible after solidification, no adverse effects from geothermal water or freezing, safe to handle and environmentally friendly, and 100+ year design life.

These containment and leachate management methods apply not only to above-ground leachate pads and settling ponds, etc. but also to all types of subsurface mining to control water flow and prevent leaks.

Sovereign Hydroseal has worked with mines in Bonne Terre Missouri for over 50 years on all their water control challenges. With our jet grouting capabilities, Sovereign can now assist in construction of leachate containment systems and soil improvement. Jet grouting complements our long-standing water sealing support to the mining industry to address challenges posed by unwanted water ingress.

We got our start in mining leak remediation in or near Bonne Terre, Missouri. This is one of the most challenging water control tasks due to the inaccessibility of leaks and the high-pressure water ingress in deep subsurface mines.

That means we can bring our 50+ years of expertise and experience, along with our NOH2O® PBE grout, to your water control challenges.

For further information or to explore project-specific information, please use our contact form, email us at info@sovereignhydroseal.com, or call us at +1 646.649.5878, and we can get started.